Key Technology Application and Case Analysis of SKL Bearings in Wind Turbines

I. Technical Challenges of Wind Turbine Bearings and SKL Solutions

Wind turbines operate for long periods in harsh environments characterized by high vibration, heavy loads, extreme temperature differences, and salt spray corrosion. Their core transmission components (main shafts, gearboxes, and pitch control systems) impose stringent reliability requirements on bearings. Through material innovation, structural optimization, and customized design, SKL bearings have targeted and resolved three major industry pain points:

· Electro-corrosion protection: Shaft currents generated by variable-frequency drives can erode bearing raceways, leading to lubrication failure and premature bearing damage. SKL's developed electrically insulated bearings feature an alumina ceramic coating that achieves a DC breakdown voltage of 5000V, blocking current paths and extending bearing service life by more than three times.

· High load capacity and fatigue resistance: Main shaft bearings of megawatt-class wind turbines must withstand dynamic loads of several hundred meganewtons. SKL adopts carburized steel materials and special surface treatment processes, enhancing resistance to micro-pitting by 50% and ensuring a design life of over 20 years.

· Space integration and lightweight design: To adapt to compact gearbox designs, SKL has launched outer ring-free cylindrical roller bearings. By integrating the raceway into the planetary gear, these bearings reduce weight and space occupation while improving radial load-bearing capacity.

II. Typical Case: Bearing Upgrade of Gearboxes in a 5MW Offshore Wind Turbine

(1) Project Background

A 5MW offshore wind turbine developed by an international wind power equipment manufacturer frequently encountered the following issues during operation:

· Planetary gear bearing slippage: The thin-walled planetary gears were prone to deformation under high radial loads, causing relative sliding between the bearing outer ring and the gear shaft, which led to abnormal wear.

· Gearbox housing deformation: Traditional full-complement cylindrical roller bearings are sensitive to housing rigidity. Fluctuations in wind loads caused micro-deformation of the housing, exacerbating bearing misalignment.

· High maintenance costs: The bearing replacement cycle was only 3–5 years, with a single shutdown maintenance cost exceeding 500,000 CNY (including hoisting, transportation, and labor expenses).

(2) SKL Solution

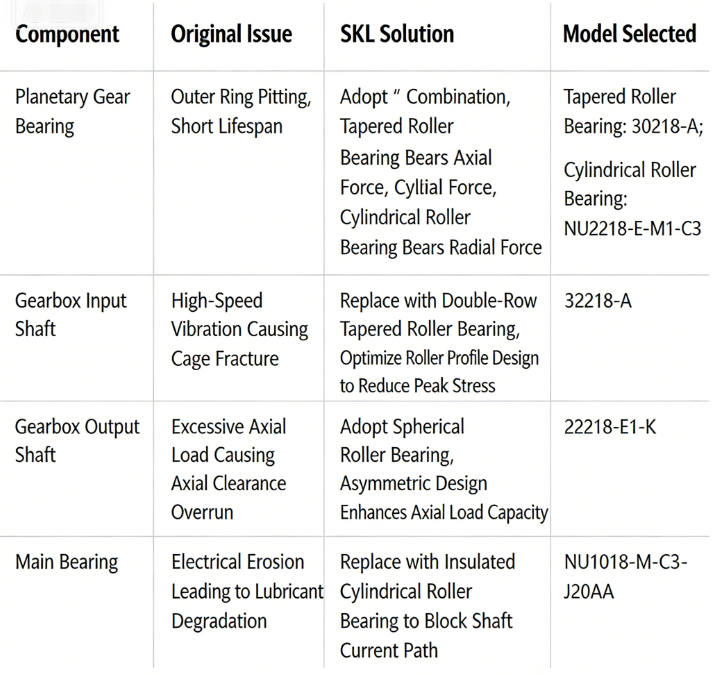

Through simulation analysis and working condition adaptation, the SKL technical team proposed the following combined solution:

(3) Implementation Effects

1. Significant service life extension

o The service life of planetary gear bearings was extended from 5 years to over 15 years, completely eliminating the slippage issue.

o The main shaft bearings stably operated for more than 60,000 hours in a salt spray environment and obtained DNV-GL certification.

2. Reduced maintenance costs

o The annual maintenance cost per unit was reduced from 1.2 million CNY to 400,000 CNY, a decrease of 67%.

o The bearing replacement cycle was extended to over 10 years, reducing unplanned shutdowns by 75%.

3. Energy efficiency optimization

o The transmission efficiency of the gearbox was increased by 1.2%, boosting annual power generation by 300,000 kWh (calculated based on a 5MW unit).

o Bearing friction losses were reduced by 20%, helping the entire unit achieve carbon emission reduction targets.

III. Technology Extension: Innovative Applications of SKL Bearings in Wind Turbines

(1) Pitch System Bearings

In response to the oscillating motion characteristics of pitch bearings, SKL has developed four-point contact ball bearings (Model QJ214-TVP). Their bidirectional axial load-bearing capacity can adapt to the dynamic adjustment of blade angles, and the solid copper cage reduces friction, ensuring a service life of over 20 years.

(2) Yaw System Bearings

To cope with the combined loads during nacelle yawing, SKL adopts crossed roller bearings (XRU Series). Their high-rigidity structure can withstand radial, axial, and overturning moments, with a positioning accuracy of ±0.05°, minimizing wind energy capture losses.

IV. Conclusion

By integrating material science, precision manufacturing, and system integration technologies, SKL bearings provide full-life-cycle reliability assurance for wind turbines. From offshore wind farms to onshore units, and from main shafts to gearboxes, SKL's customized solutions are driving the wind power industry toward higher efficiency and lower operation and maintenance costs. In the future, as the scale of wind power installed capacity continues to expand, SKL's technological innovations will continue to empower the transition to green energy.