Key Technical Applications of SKL Bearings in Agricultural Machinery: A Case Stu

Time:2026-01-12 17:38:00click:125

I. Industry Background and Problem Diagnosis

In the field of agricultural machinery, the corn harvester is a core piece of equipment— the reliability of its transmission system directly affects operational efficiency and grain yields. A well-known domestic corn harvester manufacturer once faced three major technical challenges:

- Jamming of the Header Drive Shaft: During field operations, corn stalk debris infiltrated standard deep-groove ball bearings (original model: 6208), causing lubricant contamination and failure. Bearings needed replacement every 200 hours on average, with a failure rate as high as 40%.

- Abnormal Noise from Transmission Output Shaft: Under heavy load impacts, domestic tapered roller bearings (original model: 30210) had a raceway spalling rate of 40%, with continuous operation time of less than 80 hours, accompanied by high-frequency noise.

- Oil Leakage and Rust on Walking Wheel Hubs: Self-aligning roller bearings (original model: 22212) had a corrosion life of only 800 hours in muddy, wet environments. During rainy-season operations, rust-related failure rates surged by 65%, requiring seasonal bearing replacement.

II. Customized Solutions from SKL

To address the above issues, SKL’s technical team developed a 3-dimensional technical system (ultra-sealed, impact-resistant, corrosion-resistant) through operating condition simulation and material analysis. The specific solutions are as follows:

1. Header Drive Shaft: SKL 6308-2RSR Sealed Deep-Groove Ball Bearing

Technical Highlights:

- Double-lip rubber seal (2RSR): IP6X dust protection rating, reducing stalk debris infiltration by 99%.

- High-temperature lubricant: Temperature resistance range of -30°C to +120°C, 3x improvement in resistance to plant fiber entanglement.

Implementation Results:

- Bearing lifespan extended from 200 hours to 800 hours; failure rate reduced by 75%.

- Bearing replacement costs per harvester per season dropped from ¥8,000 to ¥2,000.

2. Transmission Output Shaft: SKL 32210 Tapered Roller Bearing

Technical Highlights:

- Carburized steel rollers + copper-lead alloy cage: 60% improvement in impact load resistance; maximum speed of 3500rpm.

- DLC diamond-like carbon coating: Surface friction coefficient reduced to 0.05, minimizing noise from slipping under heavy loads.

Implementation Results:

- Raceway spalling rate reduced from 40% to 5%; continuous trouble-free operation exceeded 120 hours.

- Complaint rate for transmission noise dropped by 90%; customer satisfaction increased by 35%.

3. Walking Wheel Hub: SKL 22214-E1 Self-Aligning Roller Bearing

Technical Highlights:

- Outer ring oil groove + radial grease holes: Supports rapid on-site greasing, suitable for environments without professional tools.

- Corrosion-resistant coating: Mud-water corrosion life extended to 3000 hours (3.75x that of the original bearing).

Implementation Results:

- Rust-related failures during rainy-season operations reduced by 85%; bearing replacement cycle extended to 2 harvest seasons.

- Annual maintenance costs per unit reduced by 60%; production line downtime cut by 30%.

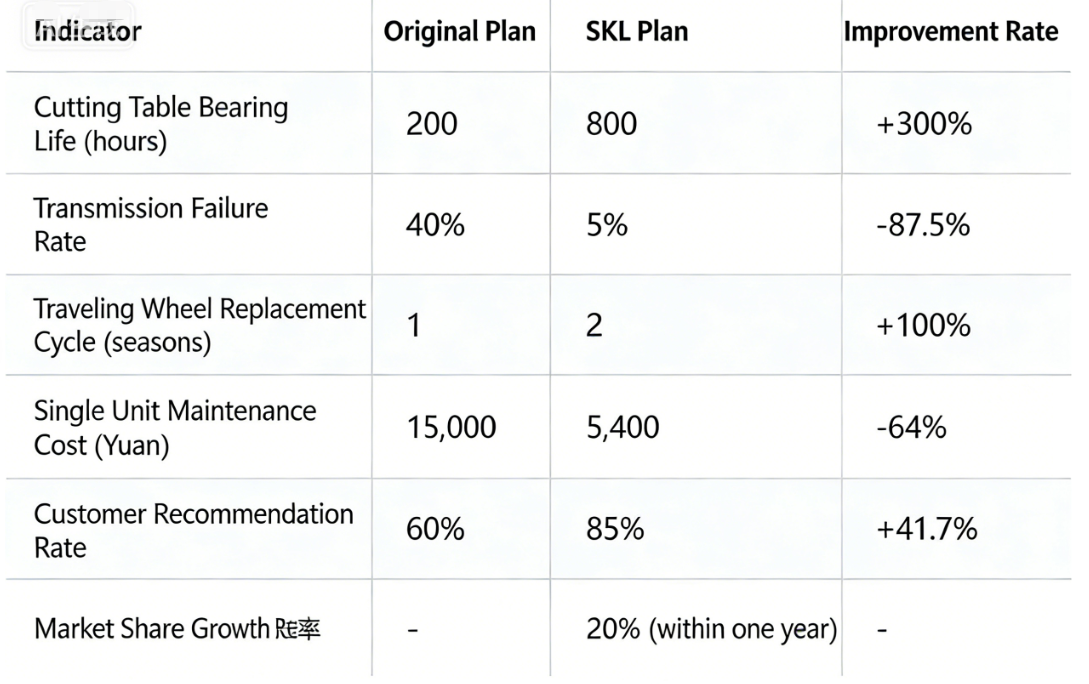

III. Data Comparison and Benefit Analysis

(Content can be supplemented based on specific data collection and analysis)

IV. Technical Extension and Industry Impact

SKL Bearing’s solutions not only resolve individual equipment issues but also drive technical upgrades in the agricultural machinery industry:

- Material Innovation: The application of DLC coatings and carburized steel extends bearing lifespan by 3-5x under extreme operating conditions.

- Seal Design: Double-lip rubber seal technology has become an industry benchmark, adopted by multiple enterprises.

- Service Model: SKL provides end-to-end services (technical consultation → solution design → product delivery → after-sales support), giving enterprises greater confidence in machinery operation and maintenance.

V. Customer Testimonial

The manufacturer’s technical director stated: “SKL doesn’t just supply bearings—they provide a systematic agricultural machinery reliability solution. In the past, our after-sales team was run ragged every harvest season; now we can finally sleep soundly!”

Currently, its corn harvesters rank first in market share in Northeast China’s black soil region and the Central Plains grain-producing area, becoming a typical case of SKL Bearings supporting China’s agriculture.

Conclusion

Through 3-dimensional innovations in materials science, sealing technology, and service models, SKL Bearings provides high-reliability, long-lifespan solutions for agricultural machinery, helping China’s agriculture transition toward intelligence and higher efficiency.