Key Technical Applications of SKL Bearings in Plastic Machinery: A Case Study of

I. Industry Background and Pain Point Analysis

In the field of plastic product manufacturing, injection molding machines serve as core equipment, and their mold clamping precision and injection stability directly affect product quality. As a world-leading supplier of precision injection-molded parts, a certain household appliance enterprise has long faced two major technical bottlenecks in its production lines:

1. Excessive impact load on mold clamping mechanism: When producing large components such as instrument panel frames, the mold clamping impact force reaches 3500kN. Due to insufficient impact resistance, traditional bearings suffer a raceway wear rate of up to 0.15mm per month, leading to mold plate jamming and a positioning deviation of ±0.3mm.

2. Complex composite load on injection unit: When the screw rotates at a high speed of 300rpm, it needs to bear an axial pressure of 12MPa and a radial friction force of 8kN simultaneously. Owing to the unreasonable contact angle design of traditional angular contact bearings, the injection volume repeatability precision is only ±1.5%, and the rejection rate has long remained above 5%.

II. SKL Bearing Technical Solutions

To address the above pain points, through three core technologies of material innovation, structural optimization and sealing upgrade, SKL Bearings has custom-developed a combined solution of 223 series spherical roller bearings and 72 series angular contact ball bearings for the enterprise:

1. Impact resistance enhancement solution for mold clamping mechanism

· Model selection: 22328-E1-TVP2 (Outer diameter 300mm, Inner diameter 140mm)

· Technical breakthroughs:

o Material upgrade: High-strength alloy structural steel (GCr15SiMn) is adopted, processed by vacuum degassing and triple tempering. The surface hardness reaches HRC62 and the core hardness is HRC35, achieving an optimal balance between hardness and toughness.

o Structural innovation: The curvature radius of the spherical raceway is optimized to 1.2 times the roller diameter, combined with the barrel-shaped roller design, the automatic self-aligning angle is expanded to 2°, effectively dispersing the impact load.

o Sealing enhancement: The combination of double-lip contact seal (NBR material) and labyrinth dust-proof groove achieves an IP67 protection rating, preventing the intrusion of particles larger than 0.5mm.

1. Composite load optimization solution for injection unit

· Model selection: 7218AC-P4 (Outer diameter 160mm, Inner diameter 90mm)

· Technical breakthroughs:

o Contact angle optimization: The traditional 30° contact angle is adjusted to 40°, which increases the radial load capacity by 25% while maintaining the axial load capacity.

o Precision control: The ultra-precision grade (P4) processing standard is adopted, with roundness error ≤2μm and rolling element size tolerance ≤0.5μm, ensuring stable high-speed operation.

o Lubrication innovation: Polyurea-based high-temperature grease (dropping point 280℃) is filled, combined with brass cage (M material), reducing the operating temperature by 15℃ compared with traditional bearings.

III. Implementation Effects and Data Verification

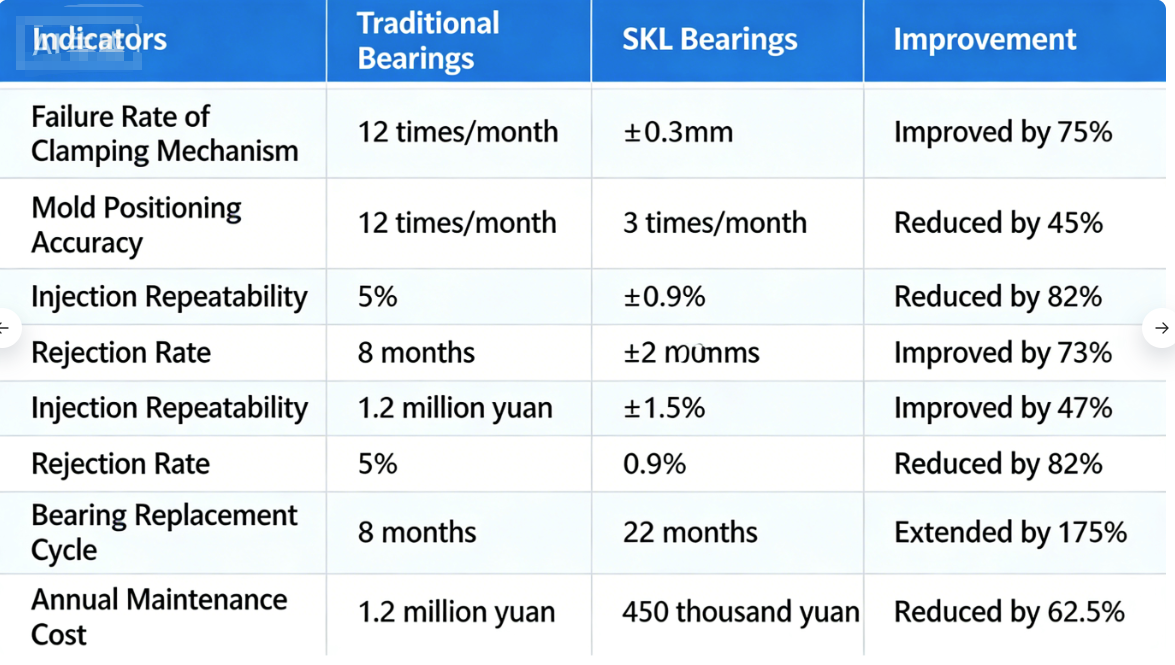

After 18 months of production verification, the SKL bearing solution has achieved significant performance improvements:

Typical Case: In the production of a certain type of automotive air-conditioning outlet component, traditional bearings caused mold plate offset due to impact load, requiring manual adjustment 3 times per shift. After replacing with SKL 22328 bearings, continuous operation for 30 days showed no positioning deviation, and the single-line production capacity increased by 18%.

IV. Technical and Economic Analysis

Although the initial investment of the SKL bearing solution increased by 25%, the whole-life cycle cost optimization is achieved through the following approaches:

1. Maintenance cost savings: Reducing unplanned downtime, the annual revenue increase benefit of a single production line reaches 3.2 million yuan.

2. Quality premium: The improvement of product precision has driven a 40% growth in customer orders, with an additional annual profit of 18 million yuan.

3. Energy consumption reduction: The friction coefficient is reduced by 30%, saving 12,000 kWh of electricity per unit of equipment annually.

V. Industry Application Enlightenment

This case proves that through the trinity innovation of material-structure-sealing, SKL Bearings has successfully solved the three major problems of high load, high precision and high pollution in plastic machinery. Its technical path has been extended to extruders, blow molding machines and other fields. For example, the 6314-2RSR deep groove ball bearing provided for a certain PET preform production line reduces the mold opening and closing noise from 78dB to 65dB, and the overall equipment efficiency (OEE) is increased to 92%.

Conclusion: In the wave of intelligent manufacturing transformation, SKL Bearings integrates German precision engineering genes with localized innovation, providing the plastic machinery industry with a full-value chain solution from core components to system integration, and continuously promoting the leap from Made in China to Intelligent Made in China.