Key Technical Applications of SKL Bearings in Variable Speed Reducers — A Case S

I. Project Background and Problem Diagnosis

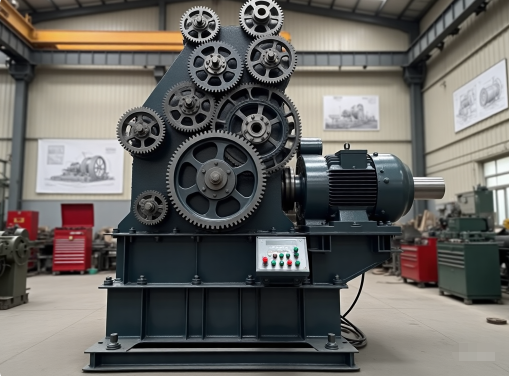

A large cement group encountered the following frequent problems during the operation of vertical mill reducers:

1. Severe Dust Ingress: The failure of traditional bearing seals led to a dust ingress volume of up to 1200mg/m³, accelerating grease contamination and bearing wear.

2. High Maintenance Costs: Bearing replacement required monthly shutdowns, with a single maintenance cost exceeding RMB 500,000 and annual maintenance costs reaching RMB 2,000,000.

3. Excessive Vibration: The equipment vibration value remained at 8.2mm/s for a long time, exceeding the industry standard (≤6.3mm/s) by 30% and affecting equipment stability.

II. SKL Bearing Technical Solutions

To address the above problems, SKL proposed a technical system of "Triple Protection + Intelligent Lubrication", with specific solutions as follows:

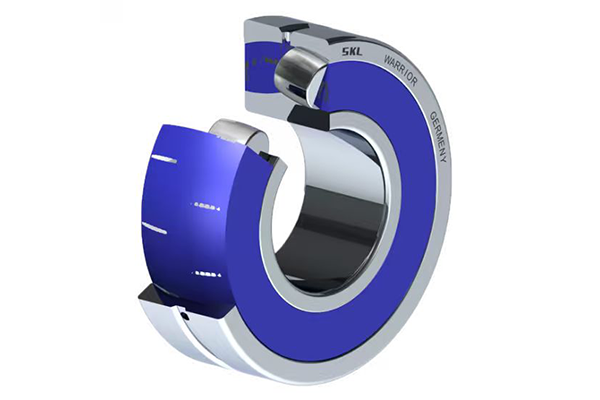

1. Sealing System Upgrade

1. Core Technology: Fluororubber + PTFE composite sealing rings are adopted to achieve dual protection of dynamic sealing and static protection.

2. Dynamic Sealing: The fluororubber sealing ring maintains a low friction coefficient of 0.2N/m within the temperature range of -40℃ to 150℃, adapting to high-speed rotation (n>3000rpm) working conditions.

3. Model Selection:

1. Sealed bearing model: 22324-E1 (Spherical Roller Bearing with Composite Sealing Ring)

2. Lubrication System Optimization

1. Core Technology: SKL solid oil bearings are introduced to achieve "on-demand oil supply" through oil-saturated polymer materials.

2. Intelligent Lubrication Cycle: When the working temperature rises, lubricating oil is released to the contact surface at a controllable rate; when the equipment stops, the oil is automatically absorbed back, reducing churning loss.

3. Increased Oil Storage Capacity: The lubricating oil storage capacity is 3-4 times that of traditional grease, and a single refueling can support 12 months of continuous operation.

4. Model Selection:

1. Solid oil bearing model: 22324-E1 (Spherical Roller Bearing Filled with Solid Oil)

3. Bearing Structure Enhancement

1. Core Technology: Steel stamped cages and high-precision raceway design are adopted to improve impact resistance.

2. Load Capacity: The rated dynamic load is increased by 25%, adapting to the heavy-load (C=1200kN) working conditions of vertical mill reducers.

3. Accuracy Grade: Reaching P5 grade (ISO standard), reducing vibration and noise.

4. Model Selection:

1. High-precision bearing model: 22324-E1 (Spherical Roller Bearing, P5 Accuracy Grade)

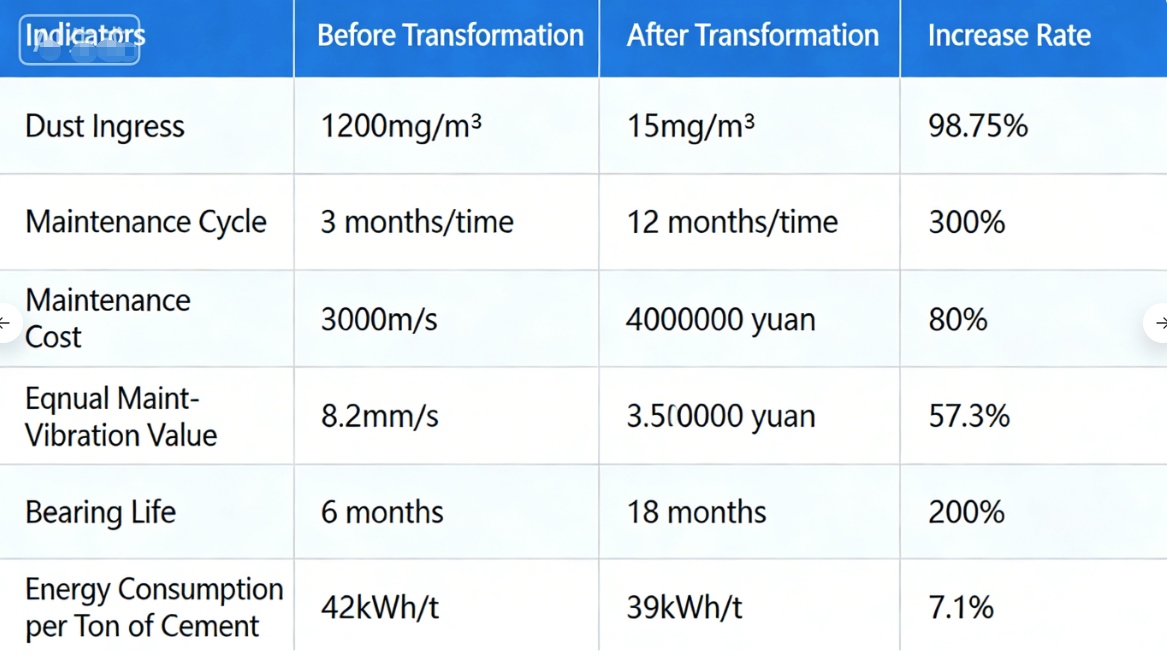

III. Implementation Effects and Data Comparison

Through the renovation with SKL bearings, the vertical mill reducer of the cement plant has achieved the following breakthroughs:

IV. Technical Principles and Industry Value

1. Innovation of Sealing System

1. Fluororubber + PTFE Composite Sealing Ring: The balance between material elastic modulus and wear resistance is achieved through molecular chain cross-linking technology, maintaining sealing integrity even under high-speed rotation working conditions.

2. Solid Oil Lubrication Mechanism

1. Oil-saturated Polymer Material: Millions of nanoscale micropores (50-200nm in diameter) in the matrix lock lubricating oil through surface tension, and the release rate has a linear relationship with temperature (R²=0.99).

3. Industry Application Prospects

1. Heavy-duty Equipment Field: In industries such as metallurgy, mining and cement, SKL bearings can reduce equipment downtime rate by more than 30% and extend bearing service life by 2-3 times.

V. Conclusion

Through sealing technology innovation, lubrication mechanism breakthrough and structural strength improvement, SKL bearings provide a full-life-cycle solution for variable speed reducers. This case proves that localized innovation of high-end bearing technology can significantly improve the reliability of industrial equipment and promote the manufacturing industry towards the goal of "zero planned downtime".